Trust the concrete experts at Multicrete to provide you with the cellular and CRF systems you need to confidently complete your project. From Autofoam cellular concrete systems to cemented rock fill slurry mixers, and foaming agents to foam generators, we carry a wide range of solutions to help ensure the safe completion of your operation.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

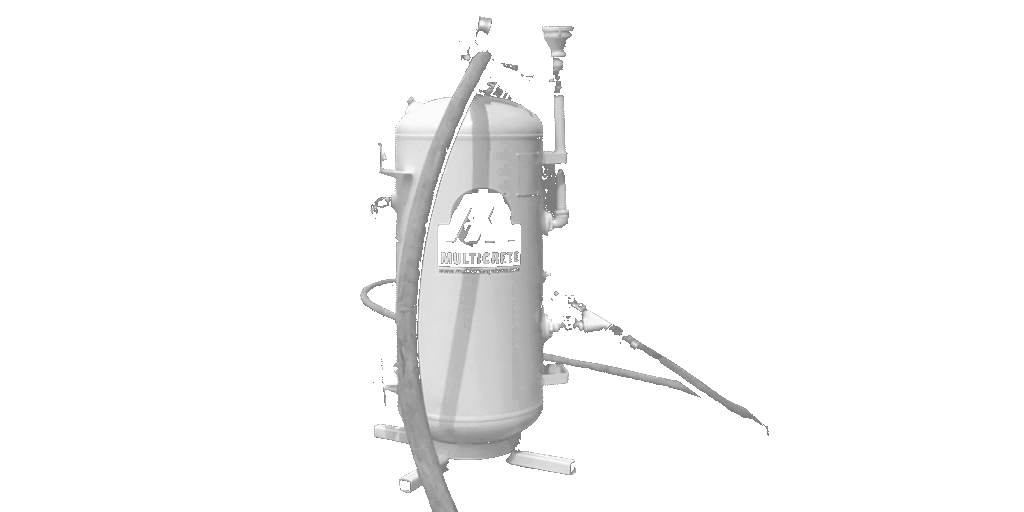

Multicrete Autofoam generators are used in the production of cellular concrete in collaboration with either continuous or batch mixing systems. All generator units include a calibrated foam nozzle with fixed foam discharge rates from 5 cfm to 40 cfm – dependent on operators flow. Pressure tank generating systems are optimal for operations where batching equipment is utilized.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

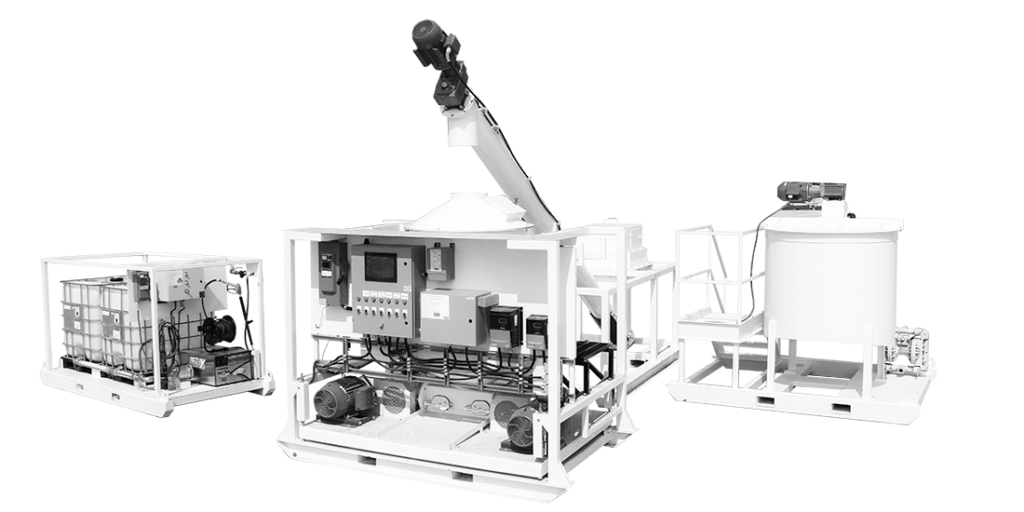

The Multicrete Autofoam Cellular Concrete System units consists of a 5-ton dry cement bin, which has the capability of feeding a 1 m³ colloidal mixer and from the mixer discharges into a 3 m³ agitator hopper.

The Autofoam system can produce 20-100 m³ per hour in densities ranging from 5 to 120 pcf.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Cemented Rock Fill Slurry Mixer is a PLC controlled single drum; high-speed, high-shear unit designed for the efficient production of cement-based slurries. The produced material exhibits colloidal properties and is homogenous in water.

The machine can handle cement/aggregate ratios up to 1:3 by weight and produce pumpable mixtures. It will mix a wide range of materials such as cement, supplementary cementitious materials (SCM’s), pre-blends, bentonite, lime or chemicals. This unit provides an output of 16 m³ per hour and a batch capacity of 1 m³ (1,000 L).

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Content needed.