Our grout equipment was uniquely developed to meet the tough demands of a variety of applications. From wheel-mounted mixers that one person can move to high-speed mixing principles that ensure maximum wetting of cement particles, you’re sure to find what you’re looking for in our selection of grout equipment.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Multicrete Twister ® was developed to efficiently mix cement-based grout for fastened production purposes. The high speed, high shear mixing principle is incorporated into the design to ensure maximum wetting of the cement particles. The intense vortex action generated in the mixer tank combined with the recirculation immediately assimilates fresh materials to be drawn through the mixer mill and are shear mixed thoroughly.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Multicrete Cobra ® is a paddle mix, modular, skid mounted mixer, engineered to be disassembled quickly for cleaning and repairs when necessary. This unit features two twin 83-gallon (314 litre) capacity mixing tanks and a 15 gallon (57 litre) holding hopper using a progressive cavity pump. A piston pump can also be equipped to this unit.

Each mixer tank has four bag breakers affixed for ease of use from either side of the grout mixer. With its ergonomic design, the Multicrete Cobra ® Grout Plant provides various safety features and a comfortable workspace when breaking bags of grout into the hopper. The tough skid design can handle all workplace conditions found on job sites and features a large skid (4 x 8″) fork slots offering mobility when relocating the unit.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Multicrete Mighty Mite ® Mixer is a low volume production skid mounted unit that is modular and locomotive. This versatile unit is designed to mix and pump neat cement, sanded grouts and most commercial pre-blended grout mixes. This unit features one 30-gallon (113 litre) mixing tanks, a 2-gallon (7.5 litre) holding hopper through a progressive cavity grout pump.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

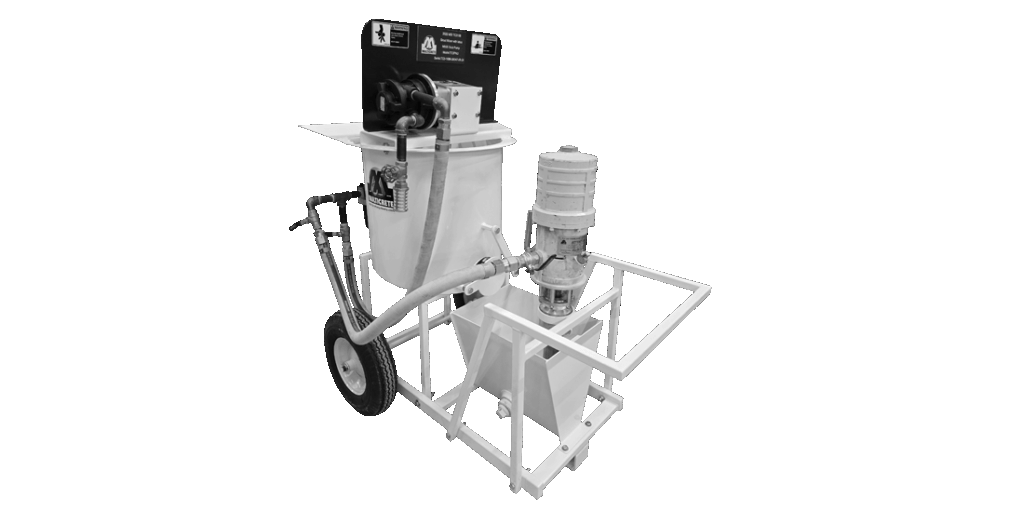

The Multicrete TC3100 ® is a lightweight, economic and easy to operate grout mixing unit used in conjunction with the ICTUS M500 Grout Pump System.

The TC3100 ® provides portable solutions for grout mixing needs. This unit is easy to use, easy to clean-up and works with existing air supplies as it is powered by a 4.6 hp vane air motor with a reducer. It mixes grout products efficiently and utilizes its 30-gallon mixing tank capacity

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Multicrete ® Air Powered Accelerator Dosing Unit is a custom fabricated unit used for dosing accelerator into cement for wet mix shotcrete. This unit features a progressive cavity dosing pump, RFL valve, adjustable flow, and is air, electric or hydraulic powered to suit your dosing needs.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Multicrete ® provides various pump options for our grout equipment lineup. This includes

Twister ® Air Model: Piston pump, progressive cavity (p/c) pump, double acting plunger pump, Hydraulic high pressure double acting plunger pumps (1000, 1500 & 2500 psi)

Progressive Cavity Pump Options

• 2L8 – 44 GPM at 176 psi – 350 RPM Pump Closed Throat Pump

• 3L8 -44 GPM at 261 psi – 350 RPM Pump Closed Throat Pump

• 2C6, 2L6 have a volume output of 22 GPM if using a pump with a maximum pressure capacity of 176 psi at 350 RPM

• 3C6, 3L6 have a volume output of 22 GPM if using a pump with a maximum pressure capacity of 261 psi at 350 RPM

• 2C6, 2L6 have a volume output of 30 GPM if using a pump with a maximum pressure capacity of 222 psi at 350 RPM

• 3C6, 3L6 have a volume output of 30 GPM if using a pump with a maximum pressure capacity of 330 psi at 350 RPM

• 2L4 – 8 GPM at 176 psi – 350 RPM Closed Throat Pump ®

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

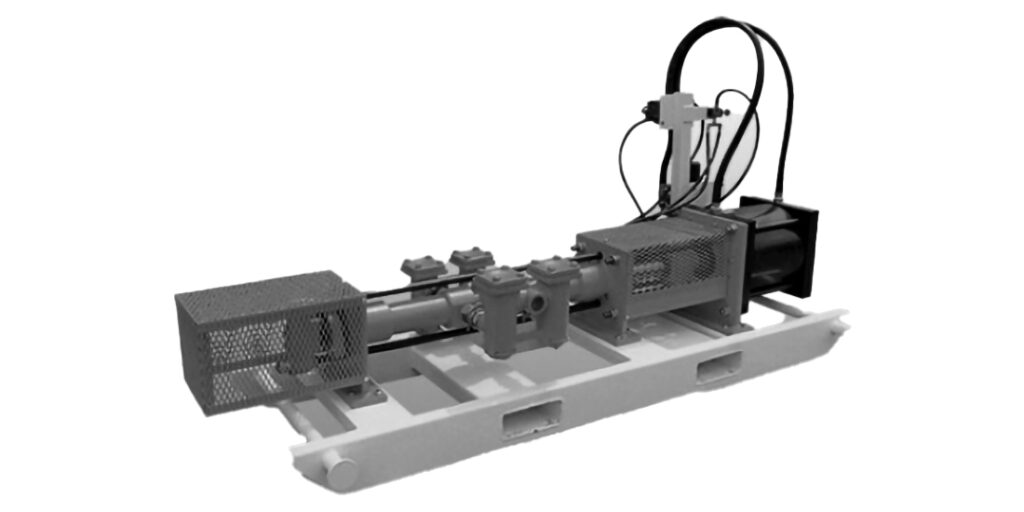

ICTUS M500 is an injection grout pump ideally used with the Multicrete TC3100 ® Mixer.

The ICTUS M500 series is a portable and lightweight, robustly constructed grout pump, mainly used for full column grouting for cable anchoring and for spraying materials, among many other applications. Combing the air motor with different riser-tube assemblies (fluid sections) will adapt the pump to suit various needs.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Multicrete ® specializes in the designing and manufacturing of grout mixing solutions including our high shear mixing units. The Multicrete Colloidal Mixer includes the following:

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Compact, simple and productive, the Mini-Series is ideal for a wide variety of construction and restoration projects.

Skid mounted and portable, the Mini-Series is ideal for most pre-packaged, non-shrink grouts and sand/cement ratios of up to 2:1.

Mini-Series features the durable 2″ positive displacement piston pump that produces up to 5 gpm, 200 to 400 psi.

A 121/2 foot grout hose (complete with fittings), and a spare set of piston cups are included with every unit.

All pumping components are easily accessible and can be disassembled without tools, for fast and efficient cleaning.

Lightweight aluminum construction offers portability for confined, hard to reach jobs.

Compact and portable, the ChemGrout Model CG-050 remains the industry’s choice for efficient grouting of smaller applications. Designed for pumping grout mixes, high viscosity slurries and premixed grouts, it delivers up to 5 gpm with pressures to 225 psi (400 psi hydraulic). Like the above

CG-050M, it utilizes a 5-gallon holding hopper and 2″ piston pump.

Engineered for minimal maintenance, the 050 has only three wetted and five working parts. Quick disconnect couplings allow for rapid disassembly in just seconds for easy maintenance and clean-up. The safe, compressed air drive is especially suited for mines, tunnels and remote sites where fuel fumes are dangerous and electricity is unavailable. Oneman operation saves both time and money.

The most powerful hand pump in the industry, the 050M provides more than 200 psi. of injection pressure.

The heavy-duty Model CG-050M is an easy to use, skid mounted hand pump designed for smaller jobs using high viscosity slurries and most pre-packaged grouts. Its rugged, lightweight aluminum construction offers mobility in areas where no air or electric power sources are available. The 050M features a large 5-gallon holding hopper and durable 2″ piston pump that produces discharge head exceeding 150 feet (ideal for vertical lifting). The manually powered, positive displacement piston pump disassembles in minutes without tools for simple cleaning and maintenance.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The CG-500 Series are balanced systems that enable high volume production and continuous mixing for a broad range of applications.

Highly versatile, the CG-500 handles a broad range of grouting applications including tunnels, shafts, dams, plant maintenance and geotechnical works. The unique twin mix tank design permits continuous pumping as each tank alternates feeding the hopper.

This non-stop pumping process maximizes the batching of materials such as neat cement, sand/cement, and most commercial pre-bagged grouts.

Two high-capacity 70-gallon mixing tanks, pump, and 15-gallon holding hopper are all mounted on a single skid for quick, easy set-up and immediate operation. The holding hopper includes an internal auger that keeps the material thoroughly mixed while supplying the pump.

The open throat grout pump features a non-pulsating positive displacement rotor-stator that provides a constant discharge of materials. This progressing cavity pump is variable speed with an output of up to 20 gpm with a standard maximum pressure of 174 psi (261 psi optional).

Soil compaction, rock grouting, void-filling, waterproofing, soil anchors, cable bolts, rock bolts, well encasements, contact grouting, well abandonment, marine/underwater, post tensioning, precast, machine base installation, self-leveling floor underlayments, slab undersealing and slabjacking.

Please refer to TDS for more details.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The versatile ChemGrout CG-550P is a complete grouting system that provides continuous operation by combining a high efficiency paddle mixer and the field proven CG-050 2″ positive displacement piston pump. Air or hydraulically powered, the skid mounted 550P features a 34-gallon mixing tank equipped with baffles, bag breakers and a variable speed high-efficiency paddle that insures rapid and thorough mixing. Once mixed, material is transferred into a 5-gallon holding hopper through a slide gate specially designed to handle the most difficult materials. Labor savings are realized using a single operator to control both the mixer and pump, increasing productivity. The rugged steel framed system stands up to the toughest job site conditions. The 550P is complete, ready for fast mobilization, and easily transported in a pick-up truck.

Please refer to TDS for more details.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

MINEPRO grout mixer/pumps are designed specifically for the mining industry.

MINEPRO pumps are used extensively for cable bolt grouting and will outperform all other existing grout pumps. They will allow the mines to install high quality, grouted cable bolts at a much lower cost than other pumps.

(9 x 20 kg bags of cement + 54 L of water)

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The ChemGrout CG-542 Series are skid-mounted grout plants specially designed for work in confined work areas. Two 22-gallon mix tanks, a 10-gallon holding hopper and progressing cavity pump provide a continuous, non-stop pumping process. Mix tanks are equipped with baffles, bag breakers and variable speed high efficiency paddles that provide rapid mixing. A unique feature of these mix tanks enables the tops to be removed for quick and easy clean up.

Once the material is mixed, it passes through the large slide gates of the tank outlet valves into the holding hopper. The 10-gallon holding hopper is equipped with an auger to keep material thoroughly mixed while waiting to advance to the pump suction housing. A positive displacement, progressing cavity, rotor-stator type pump then delivers the material to the application.

Operator controls are centrally located for efficient production.

All components are easily accessible for operating, cleaning and maintenance.

CG-542 – Simple, Compact and Efficient

Rock bolts, rock anchors pre-grouting, water infiltration control, rock/soil nails, contact grouting and shaft abandonment.

Please refer to TDS for more details.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The CG600/8CF combines the latest advances in colloidal grouting in a compact design. These field proven grout plants feature ChemGrout’s 8 cubic foot capacity “Turbomixer”, along with a rotating bridge breaker, nine cubic foot capacity vertical shaft paddle agitator, and a 3-stage size 6 closed throat progressive cavity pump. Mixer and pump are mounted on a single skid (transportable by pick-up truck) for quick, easy set-up and immediate operation.

The specially designed tanks and pumps make the ChemGrout Compact Colloidal Series both efficient and cost-effective. Water and solid materials are drawn through the high-speed diffuser type pump rotating at speeds of up to 2,000 RPM to prevent flocculation and achieve complete particle wetness. Mixing time is significantly reduced by the high shear action of the colloidal mixing pump, aided by a unique powered bridge breaker device to enhance induction. These high shear colloidal mixers have been shown to increase apparent fluidity of slurry mixes by 20% over paddle mixers, an important advantage for dam, rock and soil grouting where the ability to penetrate tight formations is necessary. For very sensitive applications such as post tension grouting, the highly efficient colloidal mixer makes possible water to cement ratios down to 0.35 by weight, resulting in very high strength grout with little or no bleed water release. After mixing, the material is transferred to the variable speed, high efficiency, agitated holding tank that maintains uniform consistency in preparation for pumping.

Post-Tensioning, tunnels, shafts, mining dam foundations, permeation grouting, soil and rock grouting, slurry walls, microfine cements, penetration grouting, waterproofing, soil anchors rock bolts, soil nails, tie backs, earth anchors, slab undersealing and contact grouting.

Please refer to TDS for more details.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.