Having the right Shotcrete equipment on the job makes all the difference. Whether you’re spraying Shotcrete in subterranean excavations, mines, or large civil construction projects, our Shotcrete equipment allows for flexible and efficient application while also reducing construction time. Find the right Shotcrete equipment for your project from our vast selection.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Raise Robot ® is a remotely controlled robotic assembly used for the spraying of shotcrete in vertical shafts. This machine is designed for the use in raises (1.5 m – 6 m in diameter) and allows for undulations along the interior surface of the raise. An A-frame structure holds the unit above the shaft and is equipped with four cameras and video recording capabilities, allowing the operation technicians to monitor the progress of the Raise Robot ® and modifying the spraying parameters if necessary.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

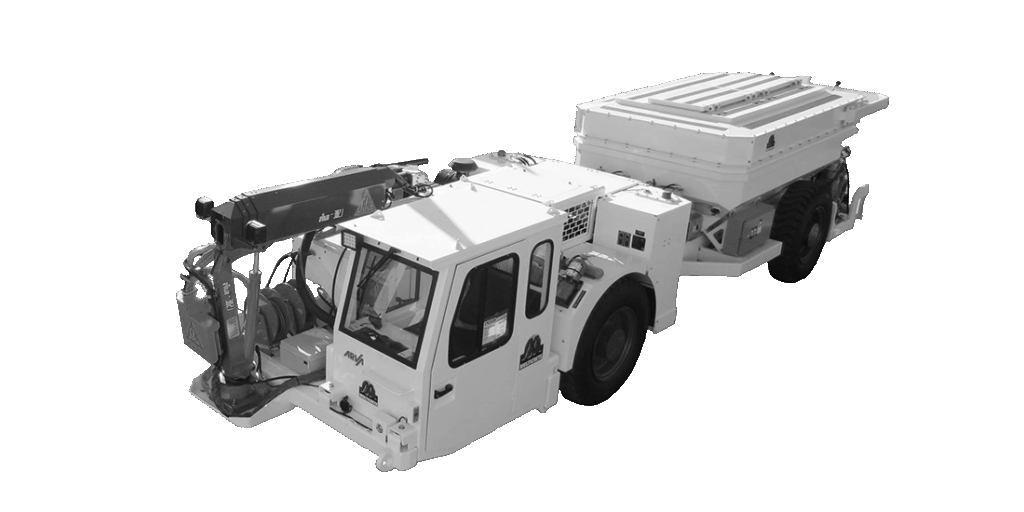

The HW10 is a hybrid wet carrier comprised of a dry mix hopper, feed auger and a mix auger. This unit wets the dry mixed material as it is conveyed; once mixed the material is pushed to the shotcrete spraying machine, allowing for the shotcrete process to begin. These pieces are all connected on a single common mobile frame.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

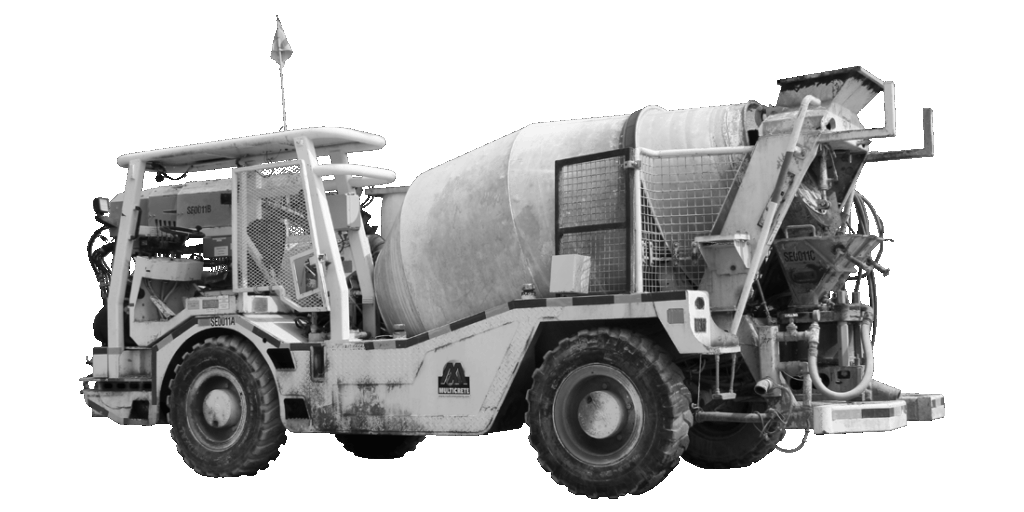

The Huron 4 is a 4m³ drum mixer truck, used for wet mix shotcrete application. This unit is comprised of a shotcrete pot, AL-302 spray arm and pumping system and are all connected on a single chassis.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

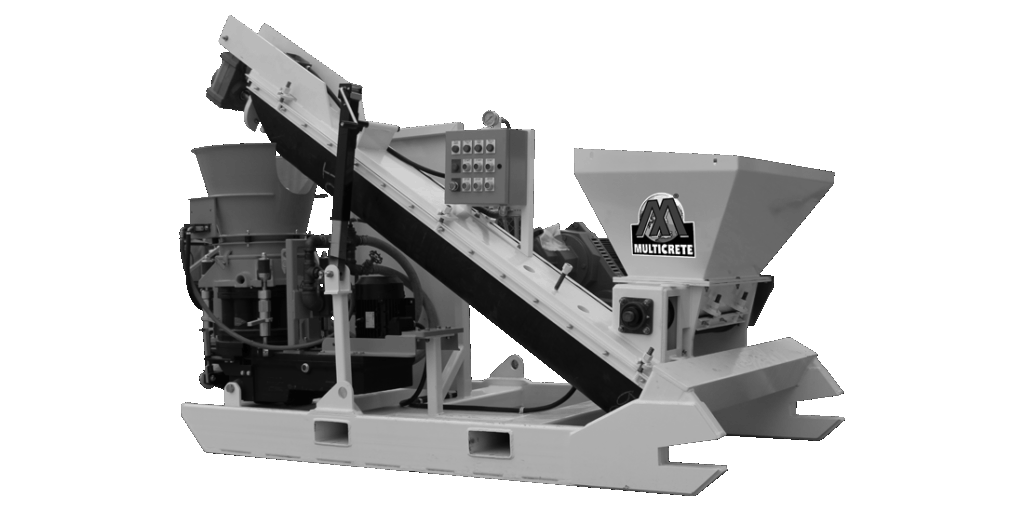

Pre-dampener and Aliva Dry Mix Shotcrete Machine Combination

This easily transported Multicrete™ Integral Shotcrete Unit consists of an Aliva dry mix shotcrete machine and a Multicrete™ Predampener, mounted together on a common frame. Preparation includes connecting the “Bull Hose” from the air supply to the inlet on the predampener frame. The water line is then connected to the spray nozzle assembly located on the mix auger. Finally, the material delivery hose can be attached to the outlet chamber assembly of the Aliva pot and shotcreting can proceed.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Shotcrete Spray Boom is a remote-controlled spraying arm used in tunneling and other underground applications. This unit can be mounted on various carriers and enables shotcrete to be sprayed in a safe and precise manner.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

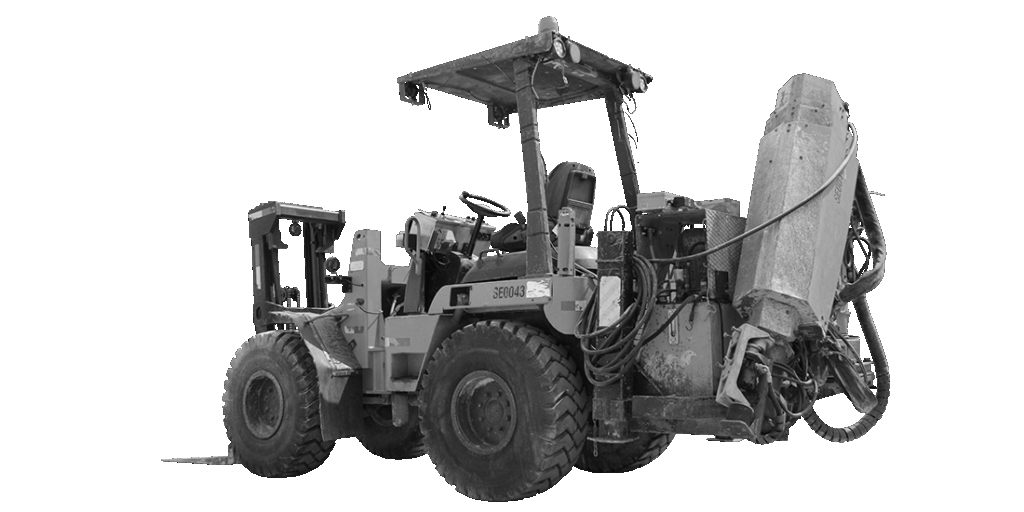

The MSU 420/302 is a completely mobile shotcrete unit, equipped with front forks, capable of moving shotcrete pots and a shotcrete boom. This unit has the capability to reach over 18 feet. These Shotcrete Units offer various shotcrete carriers and applicators for specific environment needs.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva 267 Shotcrete Spraying Machine is a compact concrete spraying machine for dry and wet shooting. With an output capacity ranging from 4 – 21 m³ / hour, the Aliva 267 is adaptable and flexible with a diverse array of applications.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva 302.1 is a robotic spraying arm used in mines and small tunnels and is designed to facilitate quick and efficient application of concrete. With its custom height reduction, easy mounting capabilities on carrier vehicles, spraying reach from 2 – 9m, and its modular design, the Aliva 302.1 is a valuable tool for various applications.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva 257 shotcrete spraying machine is a versatile concrete spraying machine useful in both dry and wet mixes in volumes ranging from 0.7 – 9.6m³/hour. With durable rubber sealing plates and robust steel plates, the Aliva 257 provides durability and versatility with minimal downtime.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva 252 unit is a robust, compact spraying machine for dry mixes, designed for demanding environments such as mines, shafts, tunnels and slope stabilization projects. With two rotor sizes and both air and electrical options available – the Aliva 252 provides long conveying distances with outputs from 5 – 11m³/hour.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva 237 unit is a compact concrete spraying machine used for dry conveying. This spraying machine comes with automatic lubrication of sealing gaskets – and an integrated frequency converter enabling variable speeds of the motor. This unit provides outputs from 0.2 – 4m³/hour suitable for various needs.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Aliva 246.5 unit is a shotcrete spraying machine used for small to mid-sized dry-mix shotcrete applications. With an output capability ranging from 0.2 – 4 m³/hour, this unit is ideal for applications such as concrete patchwork restoration, joint filling and slope stabilization. This unit is available in air or electric options.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

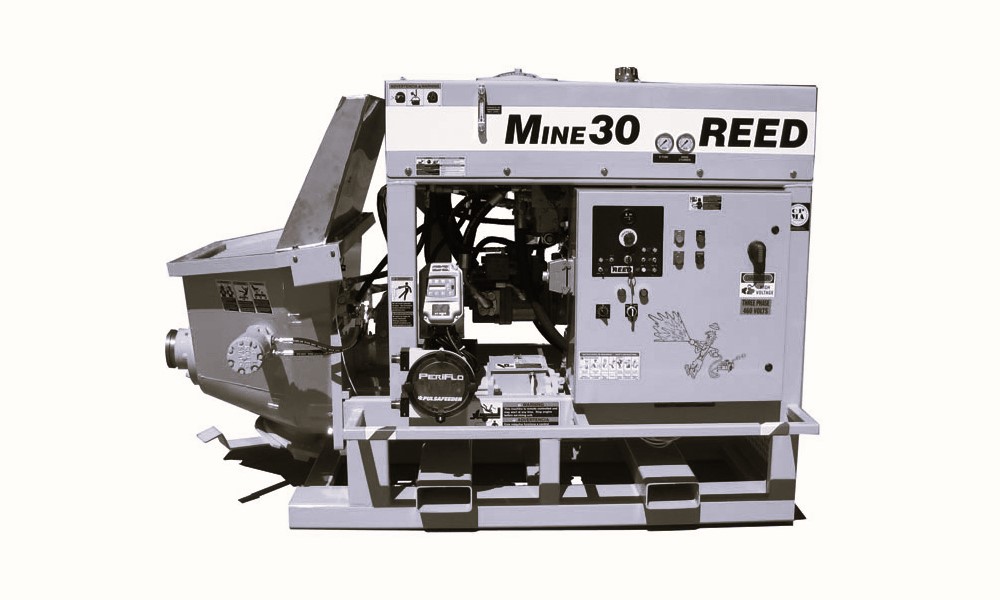

The Reed Mine 30 unit is a compact shotcrete pump often used for underground applications or applications with limited space. (96” x 46.5” x 64.7”) This unit can mount to a carrier or truck and has a maximum output of 23 m³ / hour, with a 1172 psi delivery pressure. With it’s simple design the Mine 30 is easy to troubleshoot and provides strong performance and long-term dependability.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

The Reed M2200 pan mixer is designed for the mixing of wet concrete or materials, within various specifications. The Reed M2200 provides a heavy-duty bag splitter for sprayed material dumping, variable speed mixer blade and a hydraulic motor that can run up to 59 rpm. This unit has a 3,000 lb. (1,400 kg) concrete/shotcrete batch capacity (subject to density of material.)

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Leave this alone. This accordion is here to ensure all the accordions stay closed on load.

Forklift with AL-302A Spray Arm

Multicrete Systems Inc. announces the Multicrete™ MSU R520S, a complete mobile shotcrete unit complete with front forks and a shotcrete boom with a spray capability of over 26 feet.

Make & Model Kubota, R520S C/W AL302A & 6000LB Fork Mast D1503-T-RP-1 Type Liquid cooled, 3 cylinder Turbo Diesel

Horse Power: 43.9 @ 2,600 rpm

Operating Weight: 7,275 lbs (3,300 kg)

Displacement: 134.1 cu. In.

Turbo Charger: No

E-TVCS: Yes

Overall Width: 69.3”

Wheel Base: 76.8”

Ground Clearance: 12.8”

Tread: 53.5”

Angle of Articulation: 40

Frame Oscillation:8”

FORKLIFT: 8

Maximum Lift: 10’

Forks (folding): 2-1/2” X 5”X40”

Capacity: 5500 lbs

Free Lift: Full

SHOTCRETE BOOM

Maximum Height: 26’

Maximum Length: 24’

Minimum Length: 8’

Angle of Rotation: 110

Spraying Angle: 240

Remote Control: Hydraulic

Hydraulic Aggregate: 14 L/min

Electric Drive: 5.5 kW

Or Air Drive: 7 kW

Diesel Engine: Via carrier